Trang chủ > Sản phẩm > Thiết Bị Sàng Tuyển > jaw crusher

JAW CRUSHER

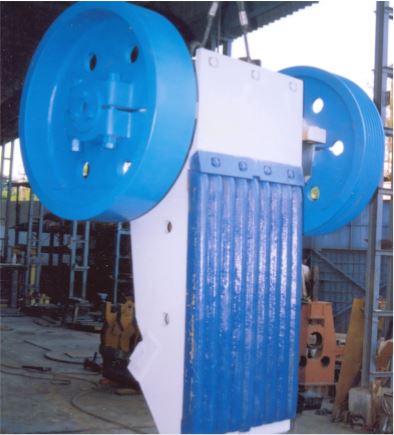

Thyssenkrupp Jaw Crushers are used for Primary Crushing. The material is crushed by compressive & shear forces. Flywheels with high moment of Inertia are generating high crushing energy & compensate crusher peak loads. The main feature of Jaw Crusher is the enhanced kinematics of the swing jaw with a high stroke feed & discharge area which ensures very high throughput rates.

ROBUST CONSTRUCTION-HIGH PRECISION-CONTINUOUS DUTY

CONSTRUCTION DETAILS

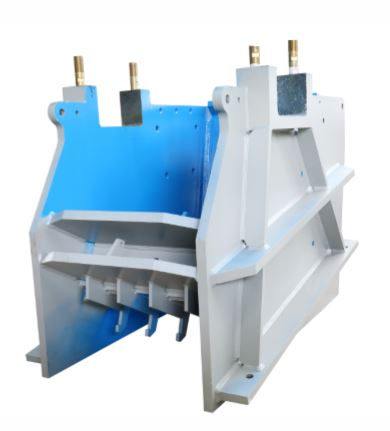

Main Frame

Fully fabricated with quality-tested weldable steel plates. Reinforced and ribbed to withstand heavy primary crushing loads. Complete frame is stress relieved for long life. Fully machined for accurate seating and alignment of all components.

Swing Jaw Assembly

The swing jaw is of robust construction, fully stress relieved and machined to provide a firm support for the jaw plate.

The jaw plates are of profiled construction and reversible for maximum wear life. The main shaft is forged alloy steel, hardened & tempered, and designed to withstand heavy primary crushing loads. Precision machined to close tolerances and fine finish, the large size main shaft offers fatigue resistance and long life. The swing jaw and main frame bearings are heavy-duty double-row roller bearings, precision assembled, grease lubricated, and fitted with foolproof labyrinth seals

against dust ingression. The bearing arrangements are designed for continuous duty applications.

Toggle and CSS Adjustment

The toggle system is designed to handle large crushing pressures. The toggle ends and toggle seats are specially prepared for smooth rocking and least friction under no lubrication environment. Manually operated hydraulic jack arrangement facilitates quick removal of toggle and closed side setting adjustment.

HIGH PERFORMANCE – LARGE VOLUMES-LOW MAINTENANCE

TECHNICAL FEATURES

- Its kinematics ensure smooth operation and long life !

- Well matched geometry and crushing dynamics !

- Totally resilient construction for high endurance against shock loads !

- Robust swing jaw of box construction !

- Large diameter eccentric main shaft of forged alloy steel !

- Grease lubricated self-aligning double row roller bearings !

- High manganese cast steel machined jaw plates, fully reversible, firmly secured and profiled for smooth flow and higher throughput !

- Lubrication free toggle and toggle seat with minimum friction !

- Hydraulic adjustment of CSS !

- Large crushing chamber, longer stroke and optimum crushing speed !

- Higher nip angle to take maximum feed size and high reduction ratio !

- Compact and well balanced suitable for fixed and mobile plants

ASSEMBLY AND TESTING

The machine is assembled under stringent quality environment, and test-run at factory for trouble free operation at site. Dispatched fully assembled for quick and ease of erection at site.

JAW CRUSHER SELECTION

Furnish following information to enable us to recommend the right size of crusher best suited to your primary crushing application.

- Feed material & its characteristics

- Bulk density and gradation of feed with maximum lumpsize

- Feeding method proposal

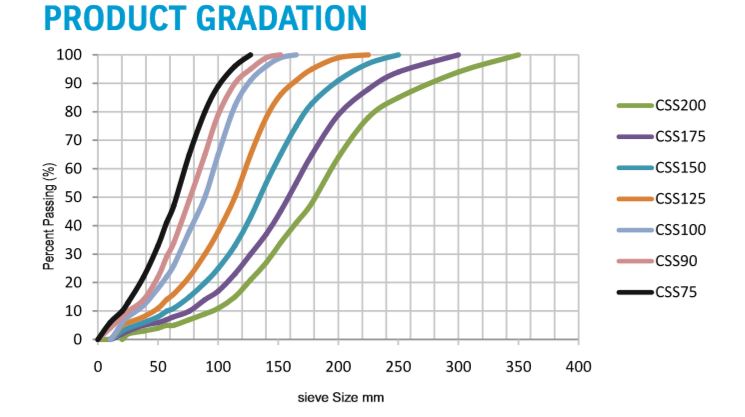

Product gradation shown are indicative only; will vary with feed gradation and material characteristics. Contact for more information

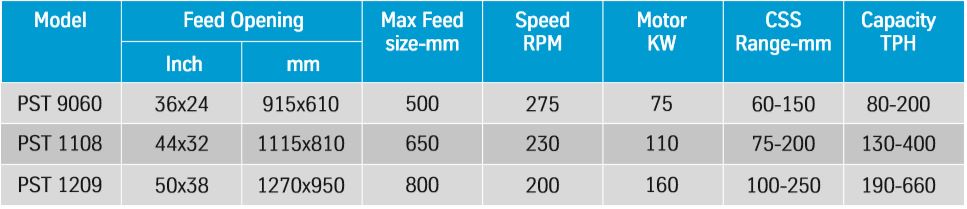

STANDARD SPECIFICATIONS

| Model | Feed Opening | Max Feed size-mm | Speed RPM | Motor KW | CSS Range-mm | Capacity TPH | |

| Inch | mm | ||||||

| PST 9060 | 36x24 | 915x610 | 500 | 275 | 75 | 60-150 | 80-200 |

| PST 1108 | 44x32 | 1115x810 | 650 | 230 | 110 | 75-200 | 130-400 |

| PST 1209 | 50x38 | 1270x950 | 800 | 200 | 160 | 100-250 | 190-660 |

Capacities based on a bulk density of 1.6 t/cu.m of hard rocks; will vary with material characteristics and application. For Final selection kindly be in touch with thyssenkrupp.